Ohio Northern University is factory upgrading their

PumpLab™ to include the addition of programmable process control. With PumpLab, students learn the characteristics of centrifugal pumping, including the phenomenon of cavitation and the development of pump performance curves. The upgrade enables users to program the pump to automatically react to pressure or flow signals to maintain specific operational scenarios, similar to how it’s done in full-scale industrial process plants.

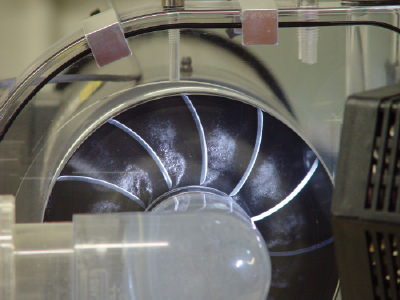

“Our Product Support Specialist, Bob Duerr is shown installing the new programmable variable frequency drive”

When Ohio Northern University acquired their PumpLab™ in 2003, they were getting a state of the art pump education system which they put to good use. Students studied the phenomenon of cavitation and learned how to develop pump performance curves with the various pump impeller profiles provided with the system.

Since that time, Turbine Technologies, Ltd. has made significant enhancements to PumpLab™. The addition of an advanced variable frequency drive, with programmable capabilities, and a new LabVIEW™ generated Virtual Instrument Panel allow students to view and control pump and process control features. These new features allow the pump to be controlled automatically through feedback signals from system pressure or flow sensors, mimicking industrial process control.

Dr. Jed Marquart, Professor of Mechanical Engineering at Ohio Northern University noticed the improved utility while at TTL’s web page. He called TTL to ask if he could upgrade his unit rather than have to buy a new one. He was very pleased to find out that he could bring his unit up to current specifications for an affordable amount.

Dr. Marquart stated: “Our PumpLab is a high quality unit that has already served us well at ONU for many years. With this extremely affordable upgrade, we look forward to many more years of continued quality education and demonstrations to our students. Our initial purchase of the PumpLab, as well as the upgrade, are funds well-invested for the sake of our students.

For additional information, visit: the Control Labs page